Posted by  Christine Gunsaullus on Monday, March 13, 2017

Christine Gunsaullus on Monday, March 13, 2017

Back when I was a young “tankie,” we built tanks with one common inlet and outlet pipe because that was the cheapest way to do it. Water quality wasn’t a consideration. I remember a few (of what I considered “over-zealous”) engineers in the 90s designed elaborate piping configurations inside some tanks to separate inlet and outlet water, adding tens of thousands of dollars to the tank price. All for what?

Well, older and wiser, I now realize this was my first exposure to tank mixing. Today, with water quality standards getting more and more stringent, plus improved mixing technologies, we always recommend that potable water tank owners consider tank mixing systems. This applies to new tanks, tanks being repainted, and tanks that have water quality issues where mixing could help.

How to Choose a Water Tank Mixing System

The first important consideration when selecting a mixing system is clearly identifying what problem(s) you’re trying to solve. Is it low chlorine residual? High water age? Stratification? Ice/Freezing? A combination of these issues? Also, understand that a mixing system that performs well in one of your tanks, may be an abysmal failure in another tank because of the numerous tank size, shape, and operational variables and factors that contribute to successful mixing.

Another critical component to solving the tank mixing puzzle: data. Without it, a mixing design can be a gamble that fails, wasting tens of thousands of dollars. In fact, we recently designed two new tanks, and with no system flow information (because the tanks were new), we couldn’t (1) be sure how the operators would run the system in the future, or (2) guarantee that a passive mixing system would work. So we specified active mixers in the tanks, ensuring complete mixing regardless of system operations, trading off the annual O&M costs.

We, as engineers, love data, and here’s an example of why you should love it too. Last week, my coworker, Rob Horvat, and I were talking with a tank owner near our Pittsburgh office about the new passive mixing system in her 250,000 gallon tank. She was pretty sure it wasn’t working. Based on the data she had, temperature readings taken at various levels inside the tank showed a drop from top to bottom, and were almost identical to readings in an adjacent 1.0 million gallon standpipe that had no mixer. Clearly, something odd was going on! Further discussion brought to light that the design inflow of 350 gpm from the nearby pump didn’t all flow into the 250,000 gallon tank; instead, some went to the 1.0 million gallon standpipe, and some fed into the system. That meant instead of 350 gpm flowing into the tank and fully mixing it in 3 hours as designed, there was as little as 50 gpm going in, and little mixing achieved due to the low flow. Mystery solved! Without the data, this tank owner would have no idea there was even a problem.

If you’re already tracking data in your potable water system and tanks, excellent! If not, here’s where to start:

- Flow rate into the tank

- Daily fill and draw rates/water levels over the course of a year

- Chlorine residual readings in and around the tank over the course of a year

- Water temperature readings at various heights/water levels in the tank over the course of several months

Getting Started

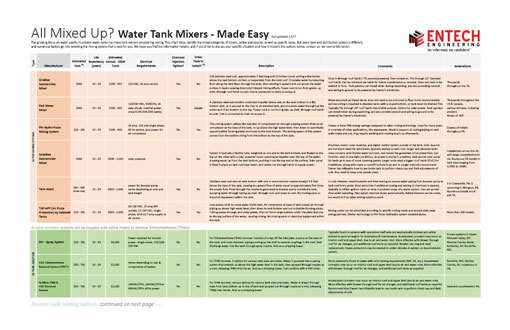

Tank Mixing Guide

Since tank mixing is still in its infancy, and the majority of the 100,000+ potable water tank owners in the United States do not have mixers, we crafted a Tank Mixing Guide to help. It starts with the broad categories of passive vs. active mixers, then delves into various mixer types, and their unique benefits and complications.

We have learned that no one mixer is the end all be all answer for all tanks, budgets, and situations, but with careful analysis of the design, data, costs, and other factors, you can be confident in a tank mixing system/design that provides complete mixing at the best value for your investment.

I love talking all things tanks, so if you’re looking for help or more information, I’m your gal!

Authored by: join enews

Categories: Municipal Infrastructure

Tagged: Potable Water